For mechanised and automated ultrasonic testing.

Ready to take the next step with us?

Intelligent solutions for measurable added value.

PHAsisROB – benefits & improvements-10_25 – EN

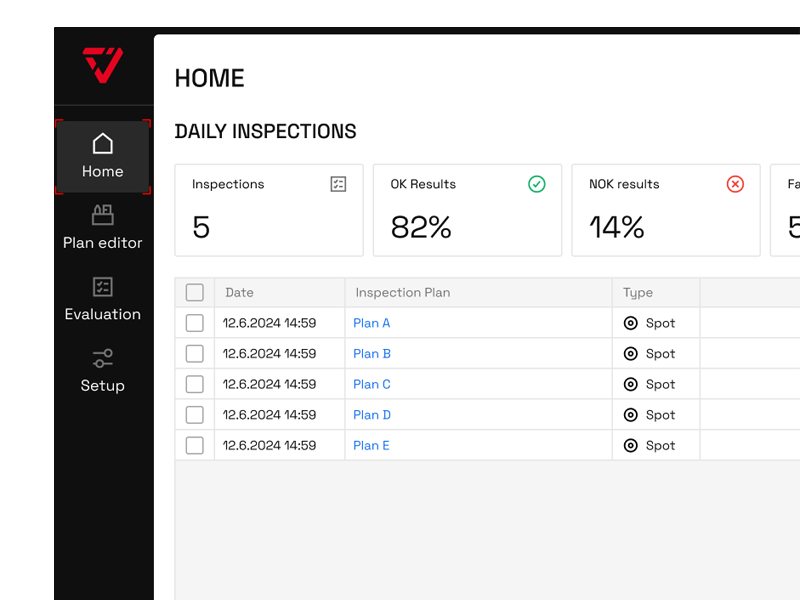

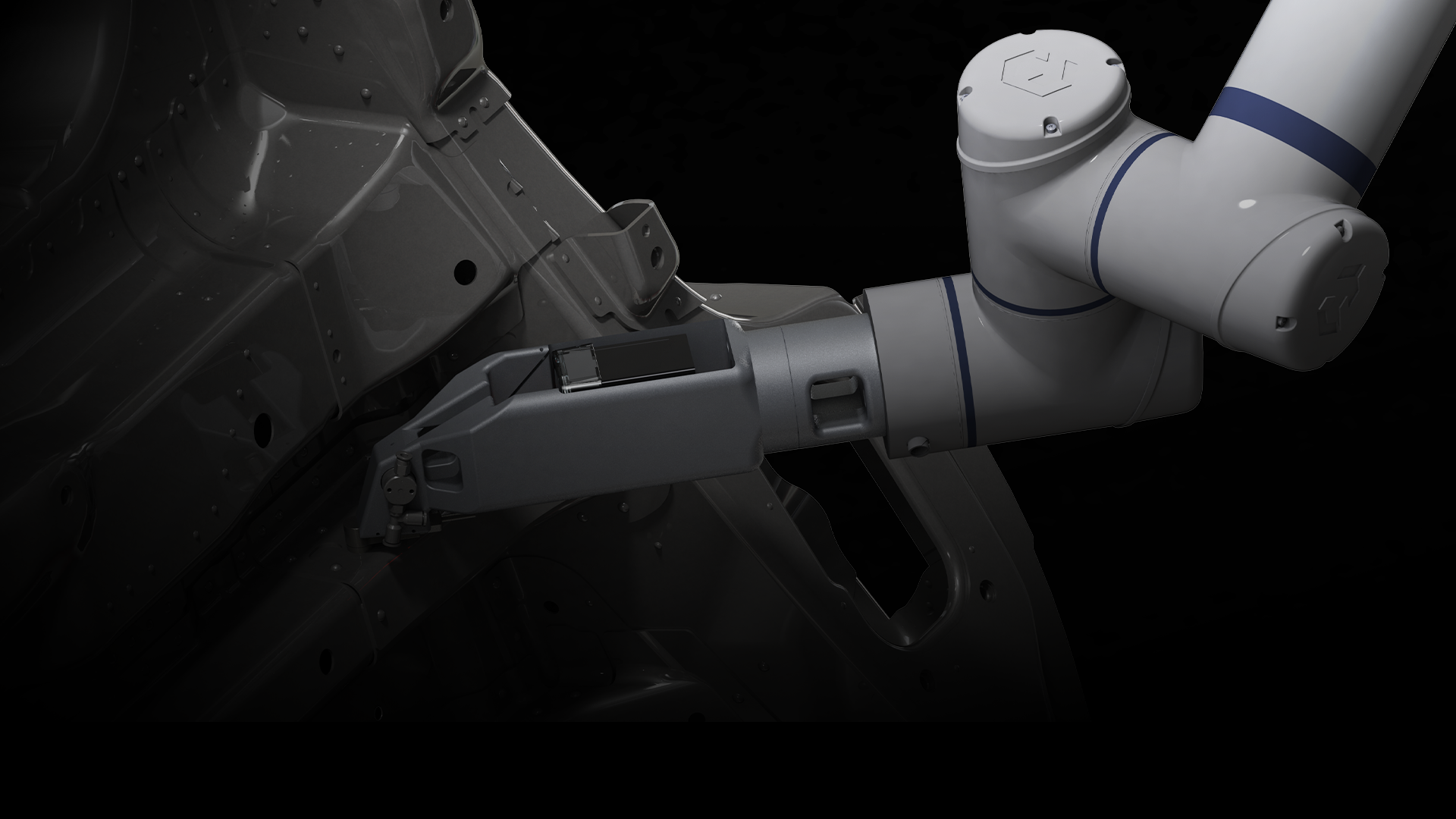

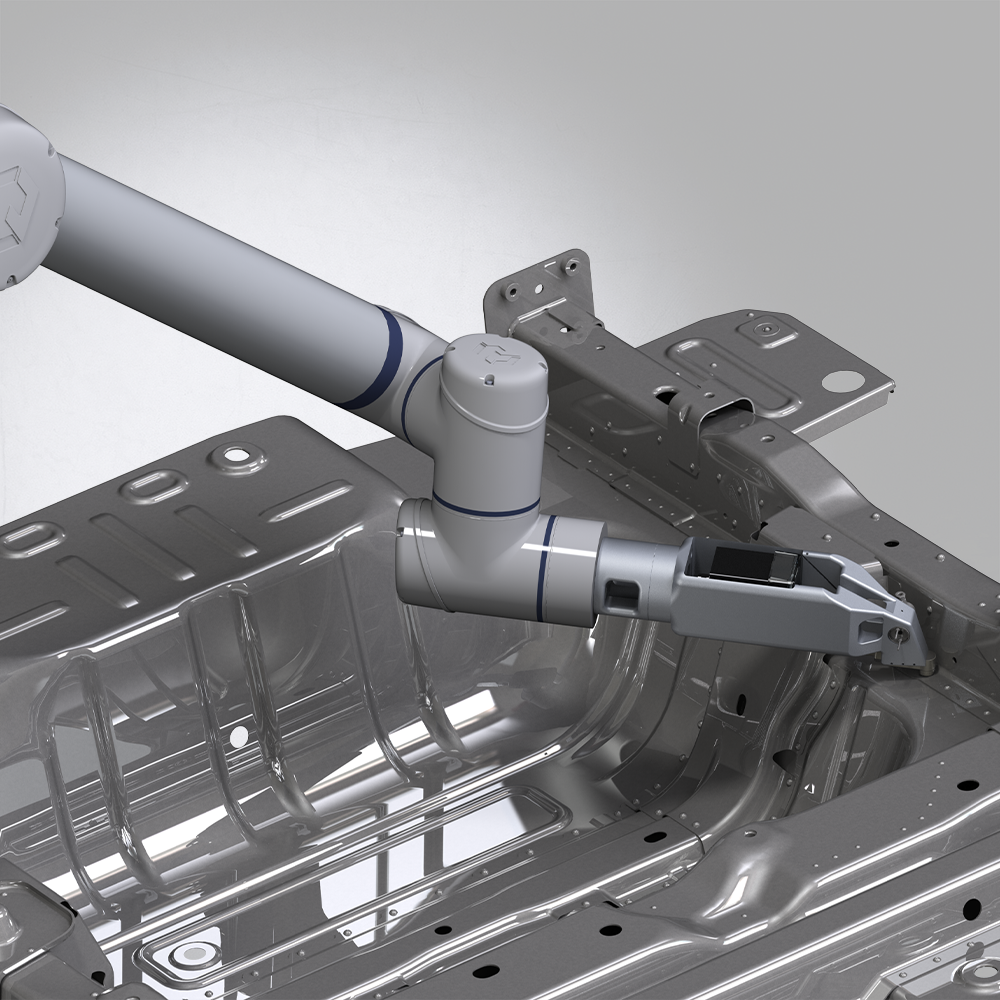

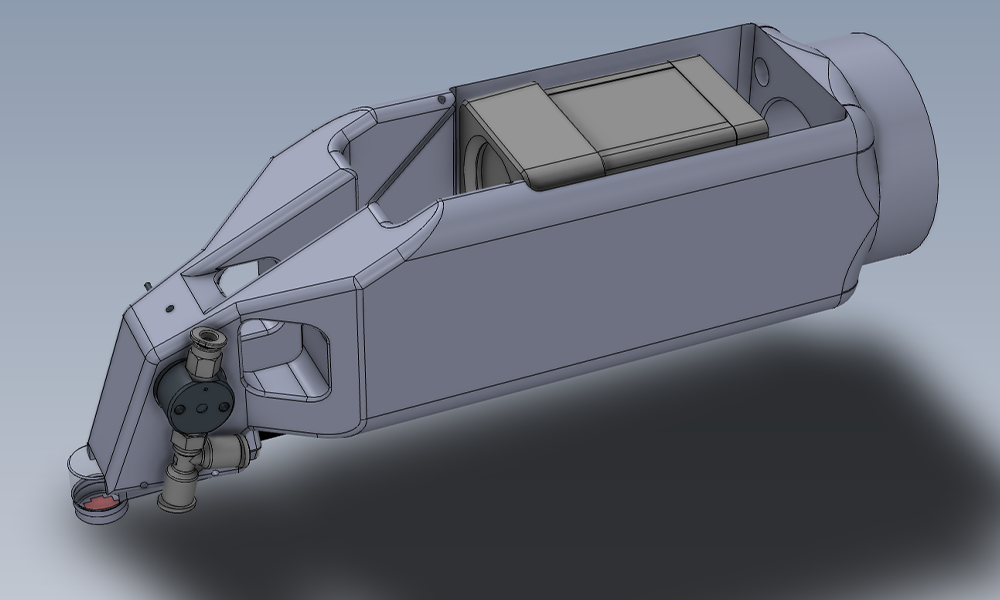

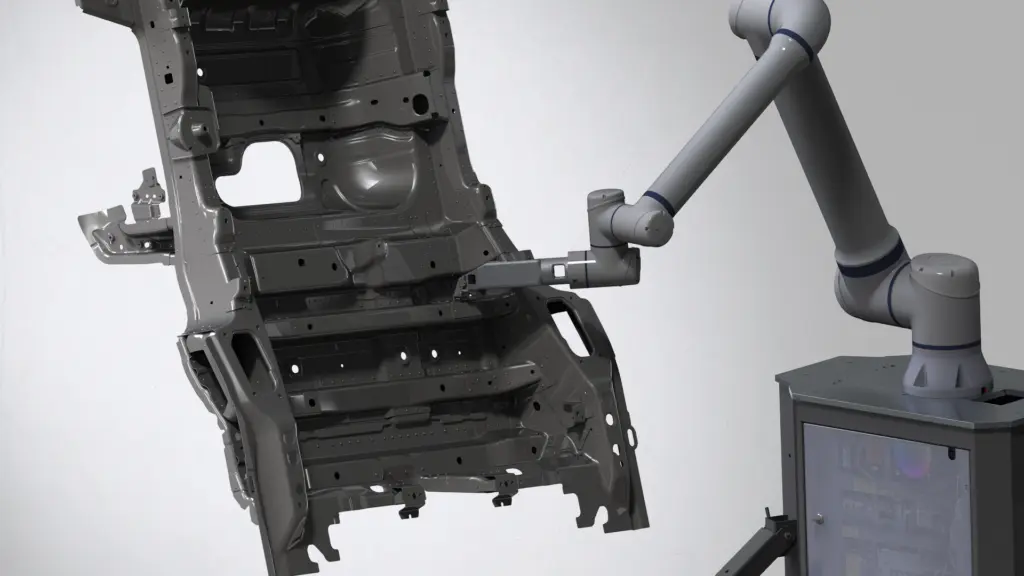

Our brochure shows how PHAsisROB is ushering in a new era of non-destructive testing through AI and robotics. The system combines modular hardware and software into a fully automated solution for weld spot testing – from CAD recognition and path planning to high-precision ultrasonic analysis.

PHAsisROBy – benefits & improvements-10_25 – EN

Find out how PHAsisROB is revolutionising industrial quality inspection in our PDF. The system combines state-of-the-art robotics, AI-based image processing and modular software for fully automated, precise and efficient spot weld inspection.